NEW Compression Platens for U-Series

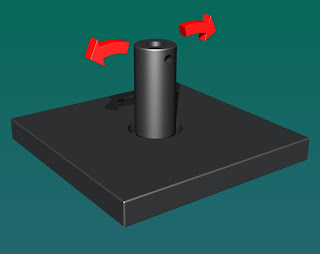

We have just addes nine new platens to our range of Compression platens, these are for use with our U-Series machine. The New platens are available in 3 different capacities, 100kN, 150kN, and 300kN. The Platens also come in 3 different Diameters, 100mm, 150mm, and 200mm.