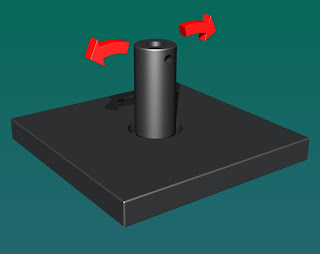

300kN Self Aligning tensile fitting

This is a 300 kN Self Aligning fitting designed for Tension testing applications only. It has an M36 lower and an M42 Upper bolt - to fit to the machine. The fitting to fitting to which you would attach the grips is M36. It meets the requirements of ASTM E8 Standard test method for tension testing metallic materials. It may also be used when working to ASTM E21-03a Elevated temperature tension tests.