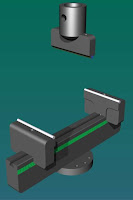

S0453 - Tinius Olsen - 100kn Seat Belt Grip

These grips are used to test seat belts and webbing up to 100mm thick. seat belts have interesting properties, they have to cushion the shock of a crash without injuring the passenger of the car at low speed stops. In a collision it has a precise elastic limit, meaning that it stretching slightly to diffuse the shock, goes beyond its elastic limit, becomes plastic then holding it's passenger without breaking, there is a great deal of force involved in this process (which is why these grips are rated to 100 kN ...) The testing can be quite explosive as the belt stores a great deal of energy before failing. By exerting a tensile force on the belt it is possible to see how it will behave. One of the important features of this grip is that it is self tightening. The specimen is feed through the grips in a specific manner as not to damage the belt. A damaged belt can dramatically affect its ability to protect the passenger, and once it has been stretched to it's elastic limit and