Revolutionising the World of Plasma and Corona Surface Treatment Systems

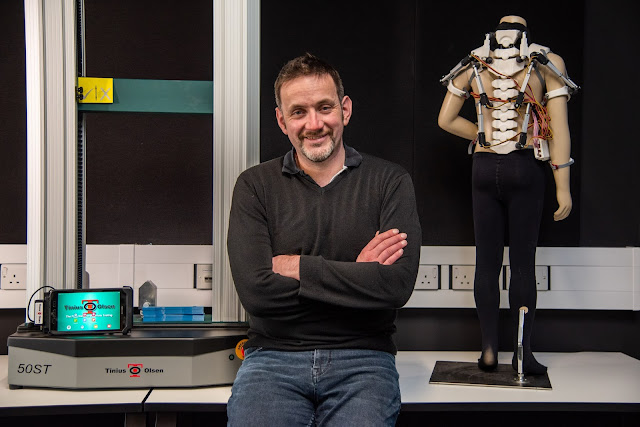

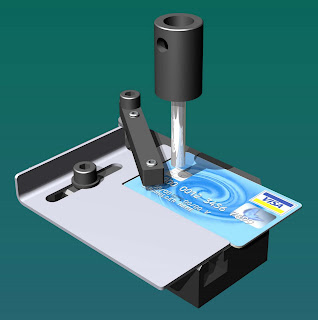

Tantec UK & Ireland manufacture Plasma and Corona Surface Treatment Systems, which improve the surface of materials, especially non-stick polymers like polypropylene, so that they can be adhered to when bonding, printing and coating. The company has a rich history supplying some of the world’s leading manufacturers since 1974, producing plasma and corona surface treatment systems for cutting-edge industries including aerospace, automotive and medical. Their products play a critical role in everyday life. Revolutionising the world of surface treatments by inventing plasma and corona systems for 3D components, Tantec have continued to operate at the forefront of the sector, being one of the few organisations worldwide specialising in both technologies. “For almost half a century we were developing thousands of surface treatment solutions and we continue to work closely with a broad range of industry sectors, supplying standard and bespoke systems to meet their requirements,” sa...