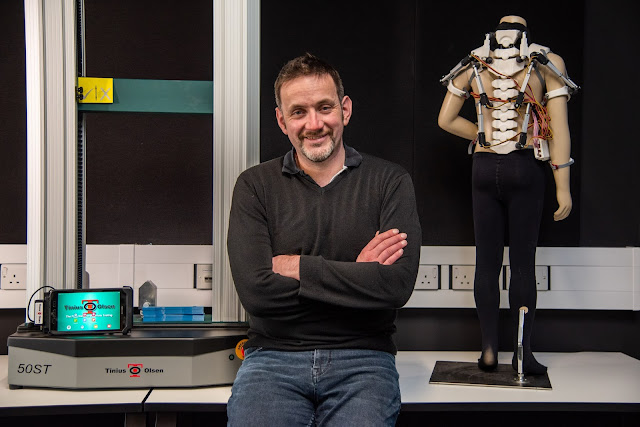

Introducing Vector – the Future of Extensometry

Tinius Olsens’ new VectorExtensometer is real a step change in extensometer technology, capable of replacing multiple contacting and non-contacting sensors with a single, industry specific instrument. Integrating adaptive AI capabilities with optical hardware, Vector reduces test throughput times and complexity, automating the process of capturing strain, improving measurement accuracy, data consistency and operator safety. This groundbreaking technology efficiently addresses practical problems by eliminating the challenges of traditional contacting and non-contacting extensometers by utilising intelligent non-contact, high-accuracy measurement techniques to: • Increase testing efficiency by reducing the need for operator intervention • Measure strain through failure, however violent • Measure simultaneously longitudinally and transverse • Test in harsh environments or challenging light conditions • Test highly fragile specimens • Avoid introducing stress concentrations, su