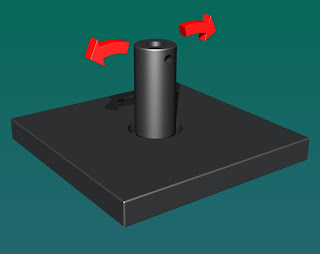

276-003 Compression Platens - With Guide

The Compression of a spring can be quite a hard thing to measure, the spring has a tendency to want to exert it's applied force horizontally to the platens (in other words, fly off under the nearest table...) This isn't really a problem, just a nuisance and in some applications a desirable feature of springs... To stop the test sample from flying off these compression platens have a free running guide that retracts into the top body. This holds onto the spring, whilst having a known affect on the test.