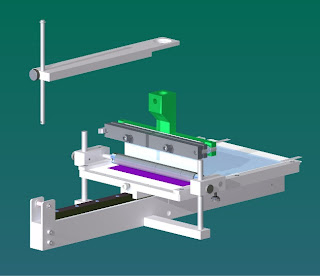

Pipe deflection measuring device

Here at Tinius Olsen, we manufacture a range of different measuring devices to measure the defletion of the material you are testing. One of these tools is the 'Pipe crush LVDT'. This tool is used in compression tests of plastic pipes to accurately measure the pipe deflection at given forces. We supply different sizes corresponding to the different pipe diameters. For more information on LVDT's or other extensometers used to measure the deflection of a sample under going test visit our main website here or contact us .