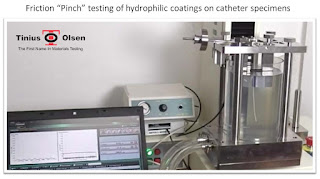

Automated Friction "Pinch" testing of Hydrophilic Coatings on Catheters

These days angioplasty, is an endovascular procedure to widen narrowed or obstructed arteries or veins, is almost considered a routine procedure, yet the technology behind it is exacting and subject to rigorous quality and performance control. In this procedure an empty, collapsed balloon, known as a balloon catheter, is passed over a wire into the narrowed locations and then inflated to a fixed size. The balloon forces expansion of the narrowing within the artery or vein and the surrounding muscular wall, opening up the blood vessel for improved flow, and the balloon is then deflated and withdrawn. A stent may, or may not, be inserted at the time of ballooning to ensure the vessel remains open.

Not only are the

stents themselves, and the wire used in their construction, tested for tensile

strength, compressive strength and stiffness properties, so too are the balloon

catheters used to deliver the stent into the body. In recent times, more

attention is being paid to the frictional properties of the hydrophilic coating

of the catheter’s outer surface must be qualified, known and controlled. At

Tinius Olsen we have developed a test system which accurately measures, and records,

the frictional forces developed between the catheter and a known surface finish

applied at a given and controlled “Pinch” force. The pinch force and surface

finish provide the known parameters for each test, so any variation in the measured

friction forces is derived from the variation in the catheter surface.

The test is a cyclic test

where the catheter specimen is repeatedly subjected to the pinch force against

the known surface finish as shown in the VIDEO CLIP Click Here .

The test is conducted within a saline solution environment which is heated to,

and maintained at, body temperature.

The output from the

Tinius Olsen system includes specific results; friction force, time, and the position

of the catheter as its cycles through the test process. It also produces test graphs

that show the catheter’s performance. It is these results and graphs which

qualify the quality and capability of the catheter’s surface coating.

Tinius Olsen systems can be configured to test the mechanical

quality and performance of a wide range of medical devices subjecting them to

tensile, compression, bending, shear, torsional, impact and hardness tests.

Comments