S0969 - Tinius Olsen - Astm D143 Wood Tension Parallel to Grain

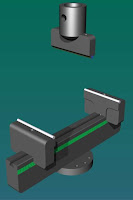

This grip is designed to meet the very strict guidelines set within the ASTM D143 standard. I have mentioned this standard before, it is one of the most demanding standards available for wood specimens. One of the most important tests when it comes to the structure of wood is how it reacts in tension. As wood can be very strong in tension it's is necessary to 'profile' the sample (cut the wood into a specific shape) so that the region undergoing test is uniform, in the middle and weaker than the grip or piece of wood the grip is holding onto. It also needs to be smaller to allow an extensometer to be added to measure the small changes in the length of the sample. This grip is essentially self-aligning, the sample slotting into the two fingers.